[dropcap style=”font-size:100px; color:#992211;”]A[/dropcap] potentially massive leap in technology comes with the advent of self-healing electronic materials which can re-establish connections after a breakage.

Pah! We knew about this stuff AGES ago. Why else would we shake our phones when the screen goes black?

Electronic materials have been a major stumbling block for the advance of flexible electronics because existing materials do not function well after breaking and healing. A new electronic material created by an international team, however, can heal all its functions automatically even after breaking multiple times. This material could improve the durability of wearable electronics.

“Wearable and bendable electronics are subject to mechanical deformation over time, which could destroy or break them,” said Qing Wang, professor of materials science and engineering, Penn State. “We wanted to find an electronic material that would repair itself to restore all of its functionality, and do so after multiple breaks.”

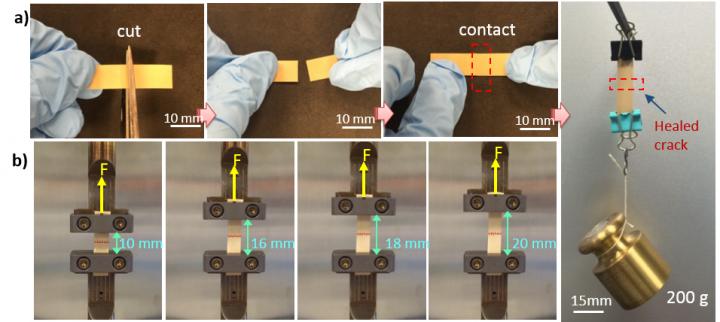

Self-healable materials are those that, after withstanding physical deformation such as being cut in half, naturally repair themselves with little to no external influence.

In the past, researchers have been able to create self-healable materials that can restore one function after breaking, but restoring a suite of functions is critical for creating effective wearable electronics. For example, if a dielectric material retains its electrical resistivity after self-healing but not its thermal conductivity, that could put electronics at risk of overheating.

The material that Wang and his team created restores all properties needed for use as a dielectric in wearable electronics — mechanical strength, breakdown strength to protect against surges, electrical resistivity, thermal conductivity and dielectric, or insulating, properties. They published their findings online in Advanced Functional Materials.

Most self-healable materials are soft or “gum-like,” said Wang, but the material he and his colleagues created is very tough in comparison. His team added boron nitride nanosheets to a base material of plastic polymer. Like graphene, boron nitride nanosheets are two dimensional, but instead of conducting electricity like graphene they resist and insulate against it.

“Most research into self-healable electronic materials has focused on electrical conductivity but dielectrics have been overlooked,” said Wang. “We need conducting elements in circuits but we also need insulation and protection for microelectronics.”

The material is able to self-heal because boron nitride nanosheets connect to one another with hydrogen bonding groups functionalized onto their surface. When two pieces are placed in close proximity, the electrostatic attraction naturally occurring between both bonding elements draws them close together. When the hydrogen bond is restored, the two pieces are “healed.” Depending on the percentage of boron nitride nanosheets added to the polymer, this self-healing may require additional heat or pressure, but some forms of the new material can self-heal at room temperature when placed next to each other.

Unlike other healable materials that use hydrogen bonds, boron nitride nanosheets are impermeable to moisture. This means that devices using this dielectric material can operate effectively within high humidity contexts such as in a shower or at a beach. “This is the first time that a self-healable material has been created that can restore multiple properties over multiple breaks, and we see this being useful across many applications,” said Wang.

Source: Eurekalert/Penn State

Image: Qing Wang, Penn State

Some of the news that we find inspiring, diverting, wrong or so very right.